The long-standing, conventional process know-how of Bowas-Induplan Chemie forms an important basis for the planning, construction of its chemical and energetic materials plants.

In addition to the planning and construction of complete new plants - turnkey plants - Bowas-Induplan Chemie also carries out the modernization of existing plants. Our focus is on safety, saving on raw materials, cost-effectiveness in energy and personnel requirements, as well as compliance with strict environmental protection requirements.

High Explosives Production Plants

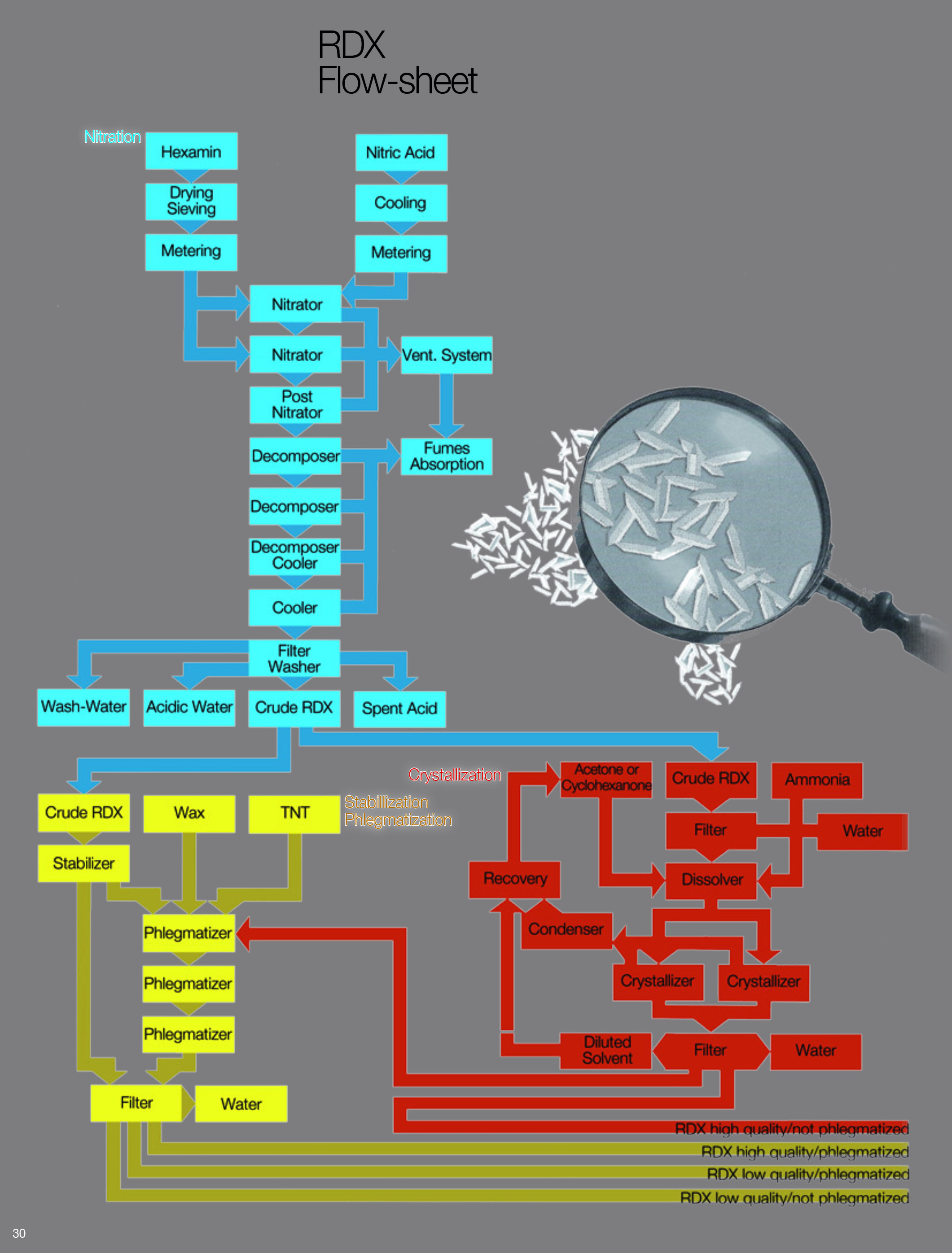

BOWAS is highly experienced in synthesis plants for various high explosives, such as RDX, HMX, PETN, NTO, TATB, HNS, TNT, as well as the equipment for the manufacture of the derivate Compositions (A, B, C, H6 etc.), Cyclotol, Hexal, Hexatonals, Torpex, Trialen etc. to load projectiles, bombs and torpedoes.

The synthesis process can be carried out either in batch or continuous nitration.

All reactors are equipped with automatic drowning devices, in order to quickly empty the content of the nitrators should a dangerous situation arise.

Raw crystalline explosives are acidic and need to be purified and stabilized. This is obtained either by pressure boiling in autoclave, by steam injectors or by crystallization from a solvent. This last process reduces residual acidity to very low levels and gives a better product. This stabilization process can be carried out continuous-wise, so the quantity of explosive in the plant is reduced to the minimum also thanks to the continuous filters, specially designed and manufactured by DMP, for crystalline explosives.