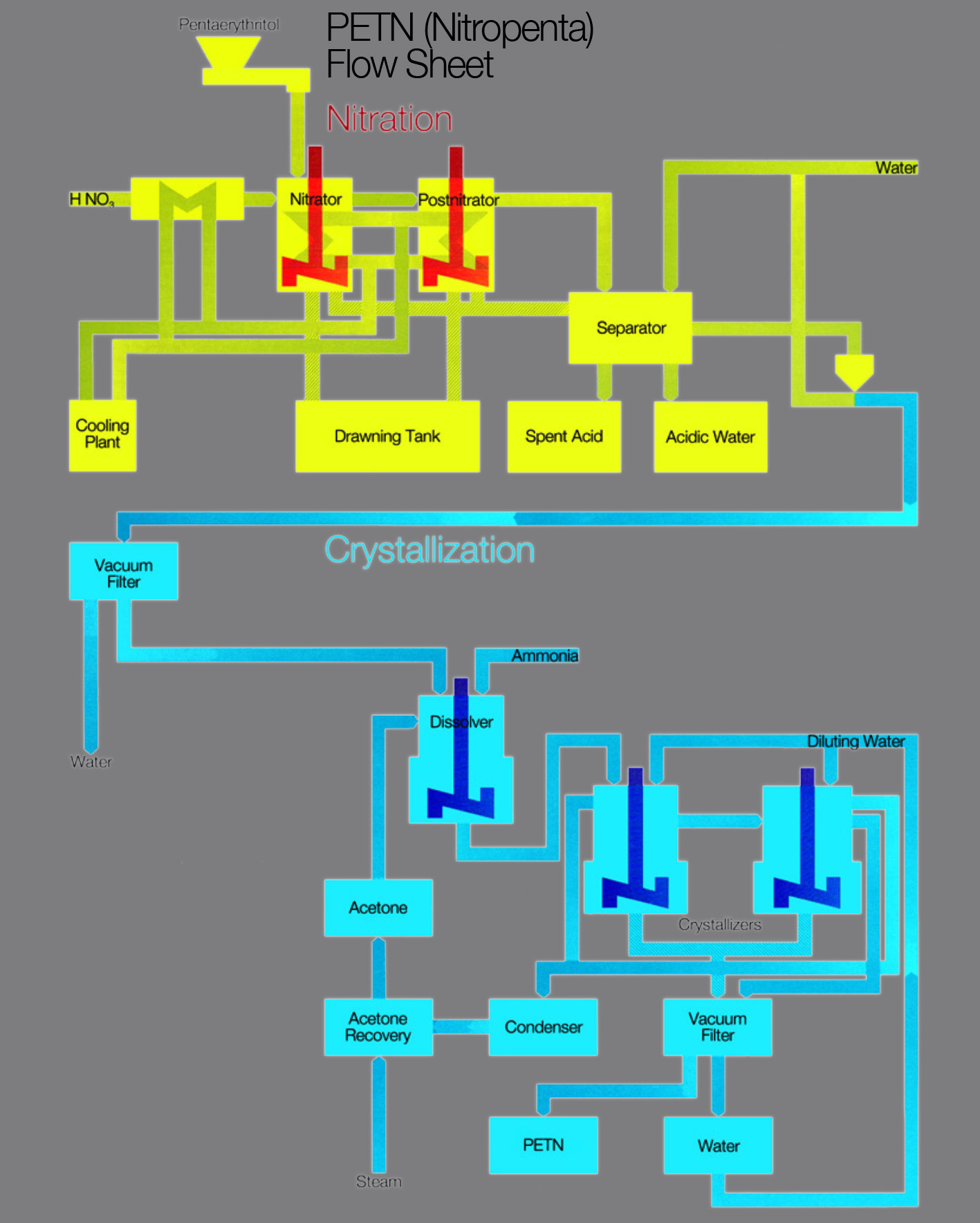

PETN Production

BOWAS is highly experienced in synthesis plants for various high explosives as well as the equipment for the manufacture of the derivate Compositions. The synthesis process can be carried out either in batch or continuous nitration. All reactors are equipped with automatic drowning devices, in order to quickly empty the content of the nitrators should a dangerous situation arise.

Raw crystalline explosives are acidic and need to be purified and stabilized. This is obtained either by pressure boiling in autoclave, by steam injectors or by crystallization from a solvent. This last process reduces residual acidity to very low levels and gives a better product. This stabilization process can be carried out continuous-wise, so the quantity of explosive in the plant is reduced to the minimum also thanks to the continuous filters, specially designed and manufactured by DMP, for crystalline explosives.

PETN Driers

BOWAS produces remotely controlled PETN driers, operated in an automatic cycle for increased safety. They are also provided with a special unloading system, which automatically fills the explosive into aluminium bottles at the end of the cycle. Only after the drying cycle's completion the operator can enter the room and drive a trolley of filled bottles to the spinning machines building.