Nitration possibilities

With almost the same basic equipment, the nitration process used in this plant allows not only the production of Nitroglycerine (NG)

but also:

- Ethyleneglycoldinitrate (EGDN) for dynamites,

- Diethyleneglycoldinitrate (DEGN) for propellants,

- Mixtures of any desired ratio of NG and EGDN or of NG and DEGN.

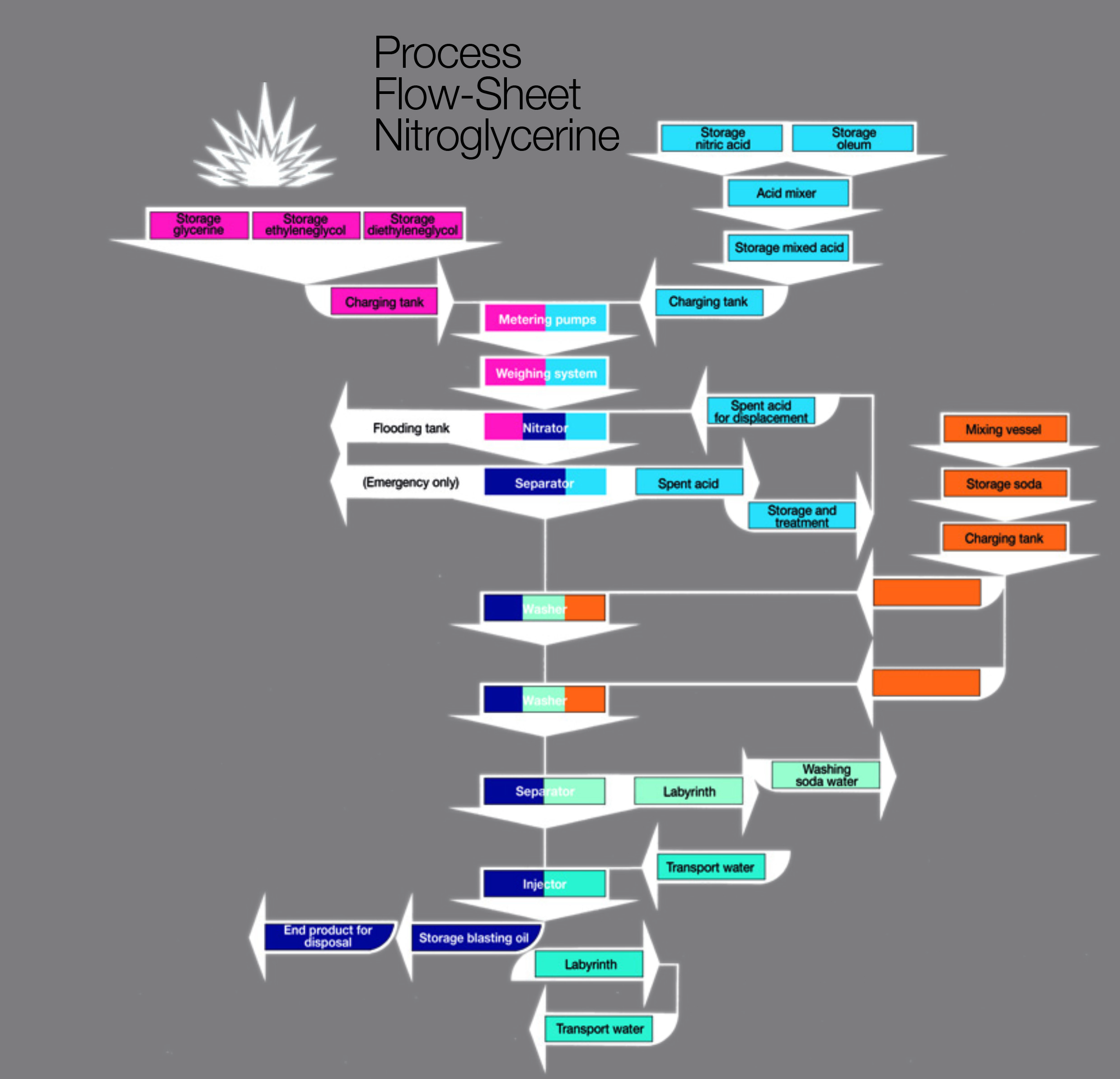

Process

The nitration process is based on the injection by metering pumps of a precise proportion of acid and organic mixtures into a nitrator with a strong stirring.

The process temperature ist automatically controlled by a very large cooling surface. The separation of blasting oil in the separator occurs by gravity without any dangerous mechanical movements.

The washing and neutralization with intermediate and final pH control guaranties an absolutely neutral blasting oil.

Safety and Advantages

A great deal of care has been taken in regard to the safety of the plant. All apparatus are designed and built in accordance with the most modern process design and current practice, recommendations and explosive design, purpose and experience. The study and the concept of the plant have resulted in increasing the yield of blasting oil and in decreasing the consumption of acid and soda without detriment to the safety. The process and its control is completely automatic. One operator has only to supervise the plant from a save room.

We offer:

1. Metering pumps

2. Weighing system

3. Nitrator

4. Separator

5. Redox

6. Flooding tank

7. Washers

8. Soda tank

9. pH

10. Final separator

11. NG-water emulsion

12. Labyrinth