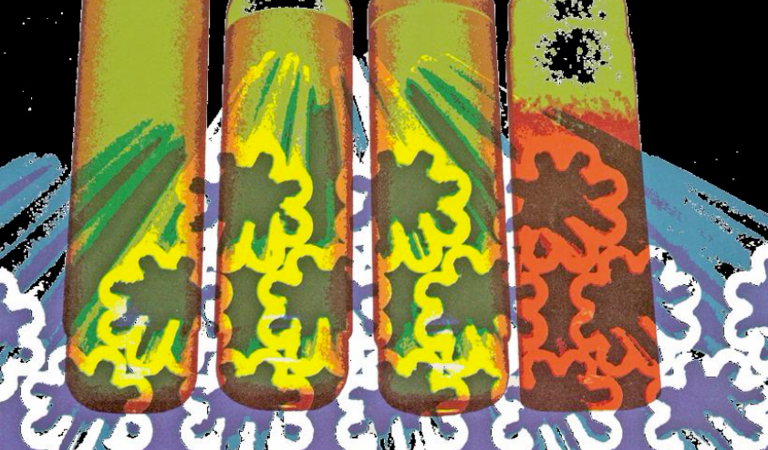

BOWAS uses an advanced manufacturing method which permits varying the composition and the wall thickness within the individual unit.

Combustible components are used in place of cloth bags or metal cartridge cases. They are manufactured from compositions on the following groups of materials:

Energetic materials (e.g. nitro- cellulose)

Reinforcing materials (e.g. kraft fibres)

Binders (e.g. artificial resins) Stabilisers (e.g.substituted ureas) Additives (e.g. talc)

Special emphasis is placed on both the mechanical combustible properties of the combustible material which are adjusted to ensure debris-free-combustion of the components in the gun.

BOWAS uses an advanced manufacturing method which permits varying the composition andthe wall thickness within the individual unit.

As a result of the energy produced on combustion, combustible components increase the efficiency of gun charges and, due to the production of a relatively cool gas stream along the barrel wall, reduce barrel erosion. After firing, no metal cartridge case remains to be ejected into the fighting compartment.

Problems

- of gun design particularly with the high gas pressure of modern high performance guns

- of logistics

- of adjusting charge increments of automatic loading of separate ammunition

can be effectively solved by the use of combustible cartridge cases